PS Food Container Production Line PS Fast food box machine makes different kinds type of fast food box, foam tray, foam cup and so on. If so, you need many moulds PS Fast Food Box Machine Fast food box machine mainly includes four parts: 1. PS Foam Sheet Extrusion Line 2. Automatic Vacuum Forming and Cutting Machine 3. Crusher and Recycle Machine This line is the whole production line, which can form lunch box from raw material. This is the recycle. The work flow is as follows: raw material---(ps foam sheet extrusion line)---foam sheet---(lunch box forming machine and cutting machine)---lunch box---(plastic recycle machine)---plastic granulars( this part can be used as raw material)----foam sheet. 1. PS Foam Sheet Extrusion Line 2. Automatic Vacuum Forming and Cutting Machine Max forming depth: 50mm Forming mode: Vacuum forming, press forming, mould forming, comprehensive forming Forming pressure: 60t (adjustable) The production efficiency:3 seconds/mould Dimension:12mx2mx2.6m Weight :28T 3. Crusher and Recycle Machine Material: PS scrap Product: Granules Screw Diameter: 350/108mm Main motor power: 15KW Pelletizer motor power: 0.75KW Total power: 25KW Throughput: 60-80kg/H Weight: 1MT Shipping 1. From Qingdao Port. 2. The shipping days according to the machine that you order. Payment 1. T/T  2. L/C   3. ESCROW CE Certification  Â

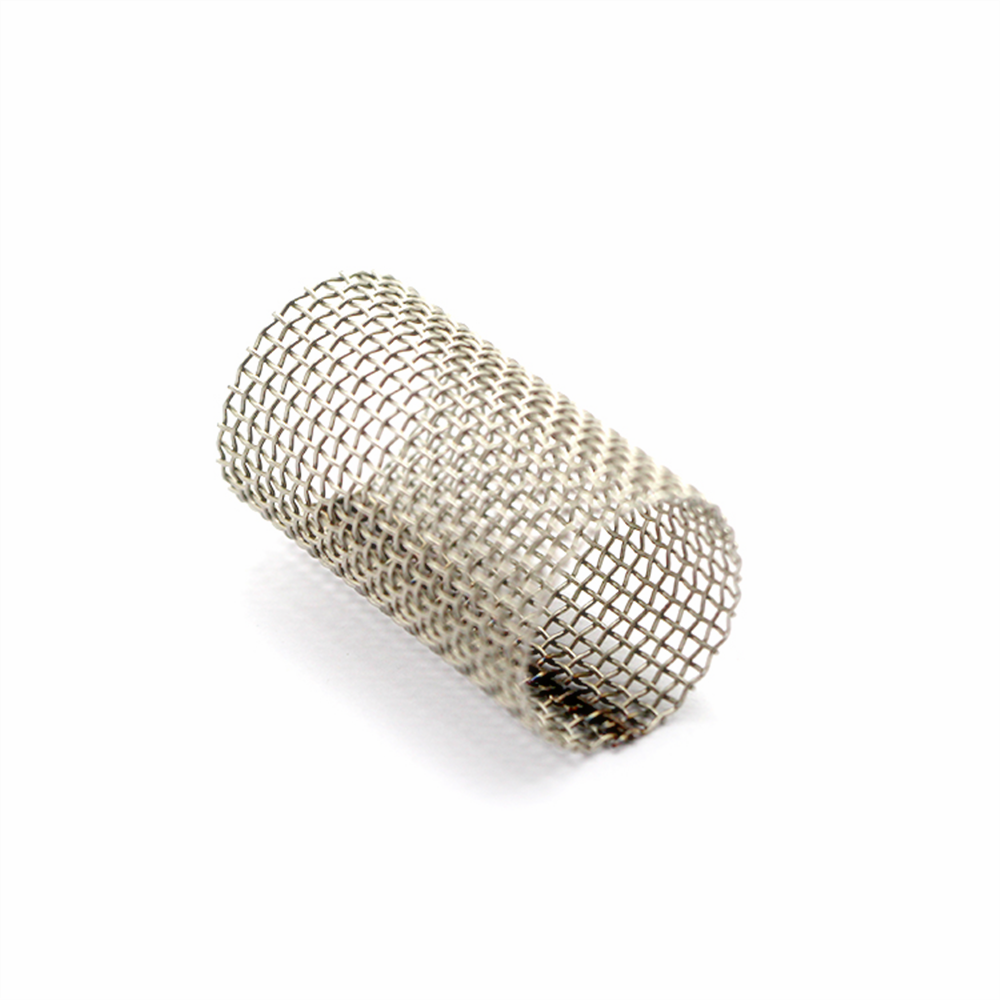

Wire mesh cylinder filter also called wire mesh

filter tube ,metal mesh filter tube ,woven wire mesh tube and so on.The wire mesh cylinder filter is made of

Stainless Steel Wire Mesh ,galvanized welded wire mesh ,metal perforated sheet,

iron wire mesh etc.

Material :SS 201.202.302.304.306.316.316L.Among

them,304 316 316L are most commonly used.

Production Process: after cutting, bending,

stamping, rolling, welding, polishing and other procedures of production.

Features for wire mesh cylinder filter: good

straightness, stainless steel material, heat resistance, corrosion resistance,

long service life.

Application

:

1)

Catalyst filtration and separation;

2) petrochemical high temperature gas

filtration, petrochemical plant boiling bed exhaust filtration, catalytic

cracking slurry filtration;

3) Purification of high-temperature flue gas in

metallurgical industry;

4) Filtration of other high-temperature gases

and liquids;

5) Filtration of high temperature, corrosive

liquid and catalyst in petrochemical industry;

6) Filtration and purification of various

polymer melts in chemical fiber film industry;

7) Filtration and separation of various

catalysts in pharmaceutical industry;

8) For gas distribution, liquid bed hole plate

material;

9) Used for high pressure backwash oil filter,

etc.;

10) Various grout for filtering edible oil,

beverage and food;

11) Used to purify and filter production

sewage.

SS304 Cylinder Filter Tube,Woven Mesh Screen Tube ,Metal Mesh Cylinder Filter Suzhou Haoxiang Screen Stencil Products Co.,Ltd , https://www.shaiwanghaoxiang.comSpecifications

1.Widely used.Â

2.PS can be recycled.Â

3.Simplicity of operator..

Max forming area: 1100mmx1400mm

Â

Foam Fast Box Making Machine for Making EPS Lunch Box

Model NO.: FS-YTB110-140

Trademark: FUSHI

Transport Package: Standard Export Packing

Specification: 30X30X3m

Origin: Longkoushandong

HS Code: 84772090